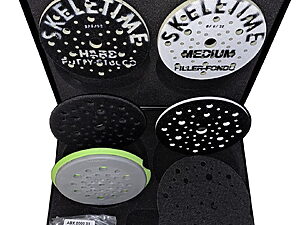

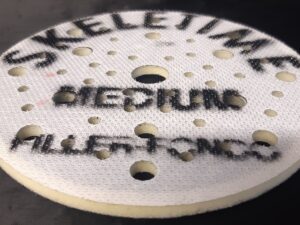

Thanks to its support patent for the hard and flexible abrasive that surrounds the parts of the aircraft, the surface with the impurities to be removed is totally zeroed and has no steps.

This process, with the same brand and abrasive grain, releases a finer sanding, with the advantage of the subsequent working phases.