The aircraft industry is constantly on the lookout for innovative solutions. The Skeletime system solves the problems of the sanding world to obtain a perfect surface.

The outer and inner skin of aircrafts is a harmonious blend of metal, plastic and composite fibers of various shapes and complex profiles that must be covered with protective coatings. Their weight plays an important role in fuel consumption.

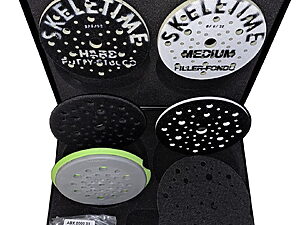

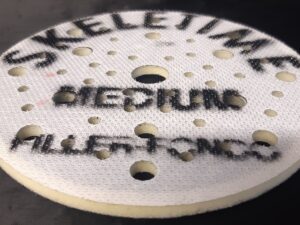

Skeletime self-adapts to each aircraft shape during the sanding phase, creating, with the same grit of abrasive used, a better surface finish.

Primary objective: containment of excess coating materials

Skeletime also reduces downtime costs, thanks to its patented system, which cuts down on sanding time and consumption.